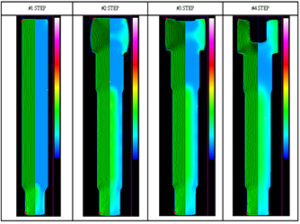

Samyang Metal has established an integrated in-house system covering everything from die design and production to maintenance, in order to strengthen process security and ensure quality. Based on this system, we apply advanced cold forming techniques that surpass traditional machining methods (such as Hobbing), enabling the production of precision-forged components. We operate a systematic manufacturing process with the goal of achieving the following results.

Samyang Metal operates the entire process—from die design and forging to machining—using in-house equipment, offering the following benefits :

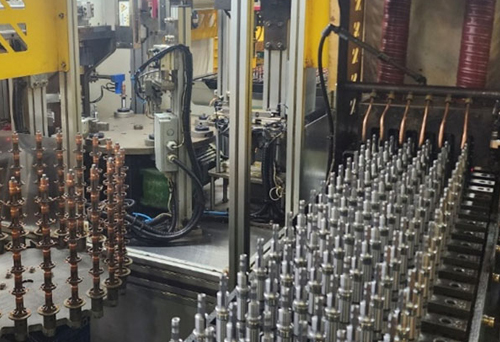

Samyang Metal operates the entire production process—from planning to final product—using its own facilities and proprietary technologies. Samyang has established a one-stop manufacturing system that covers everything from die design, cold forging, precision machining, heat treatment, and surface treatment, to quality inspection, assembly, and packing. This enables us to deliver high quality, short lead times, and flexible production capabilities.

Samyang Metal conducts research and development across various metal processing fields centered on cold forging technology. We continuously develop high-quality, high-efficiency, and eco-friendly solutions for next-generation industries.

Samyang Metal’s precision cold forging technology is widely applied across various industries, including automotive parts, electronic components, and machinery parts. It plays a key role in reducing product weight, improving durability, and lowering manufacturing costs.

Samyang Metal internalizes technology through research and development, enabling us to deliver the quality our customers demand more quickly and accurately.

Join Samyang Metal in setting the standard for future manufacturing technologies!