Samyang Metal is an automotive parts manufacturer that specializes in Cold Forging technology. Since its founding in 1985, the company has steadily grown by producing high-strength, high-precision components essential to the automotive industry.

To supply key components that require strong internal structure and high precision in all areas of the parts industry, Samyang Metal has adopted the latest cold forging technology and automated production systems. Through this, the company has established itself as a trusted partner that reliably delivers high-quality components to its customers.

In particular, Samyang Metal specializes in producing shafts—essential for automotive powertrains, steering systems, and engines—as well as various other cold-forged components, using its expertise developed over many years. The company also provides customized solutions to meet diverse customer demands and is actively engaged in R&D to apply its technologies to future industries, including robotics and aerospace.

Hello Dear Customers,

We sincerely thank you for visiting the Samyang Metal homepage.

Since its founding in 1985, Samyang Metal has grown into a leading company in the automotive parts industry based on its expertise in cold forging technology. The automotive parts market requires constant innovation and quality improvement, and Samyang Metal provides customers with precise and durable parts through continuous research and development(R&D) and technological innovation.

Cold forging is one of the most critical processes in automotive parts manufacturing. It is widely recognized for its durability, precision, and eco-friendly nature. Samyang Metal has implemented cutting-edge automated production systems and rigorous quality control frameworks to achieve the highest levels of quality and efficiency. As a result, we have earned recognition not only in Korea but also in global markets.

“Customer Trust as the Top Priority”

Our top priority is the success of our customers. We are committed to growing alongside them by providing top-quality products, excellent service, and continuous technological innovation. Furthermore, as a responsible and ethical company, we are dedicated to sustainable management practices that consider the environment and fulfill our social responsibilities.

Looking ahead, Samyang Metal will continue to take on new challenges and lead the future not only in the automotive industry but also in the fields of robotics and aerospace components, as a specialized company in cold forging technology.

We sincerely appreciate your continued interest and support and promise to grow together with you.

Thank you.

Dec. 1985 - Samyang Industrial Co., Ltd. Established

Feb. 1986 - Started production of clutch parts for automobiles

Apr. 1989 - Registered as an excellent company by

Korea Atomic Energy Research Institute.

May 1997 - Established the “Samyang Metal Co., Ltd.”

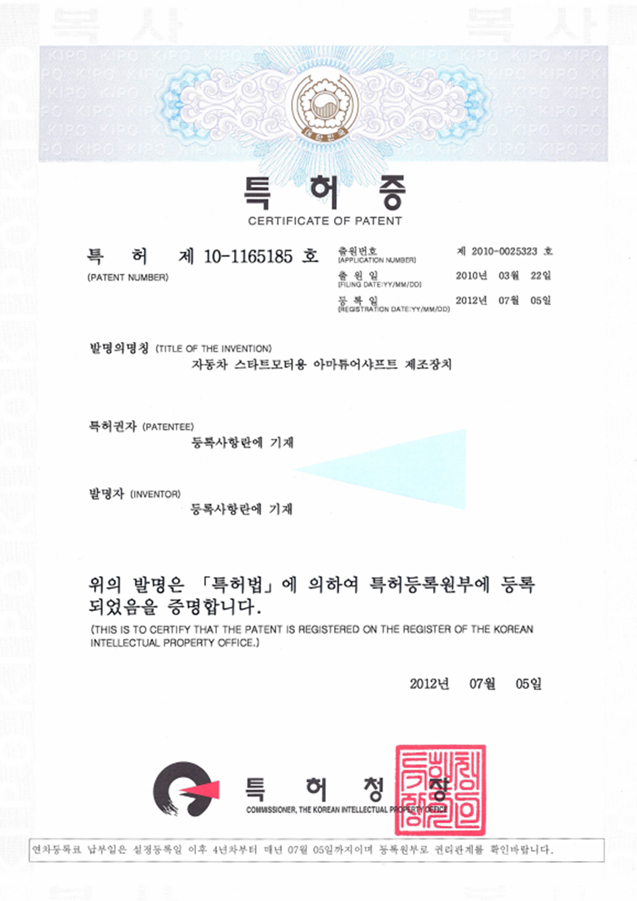

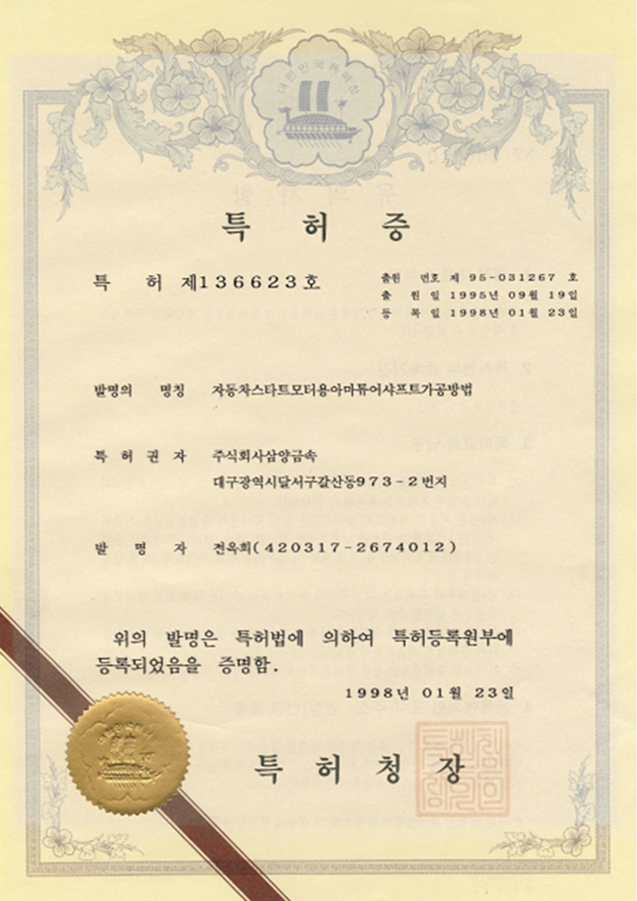

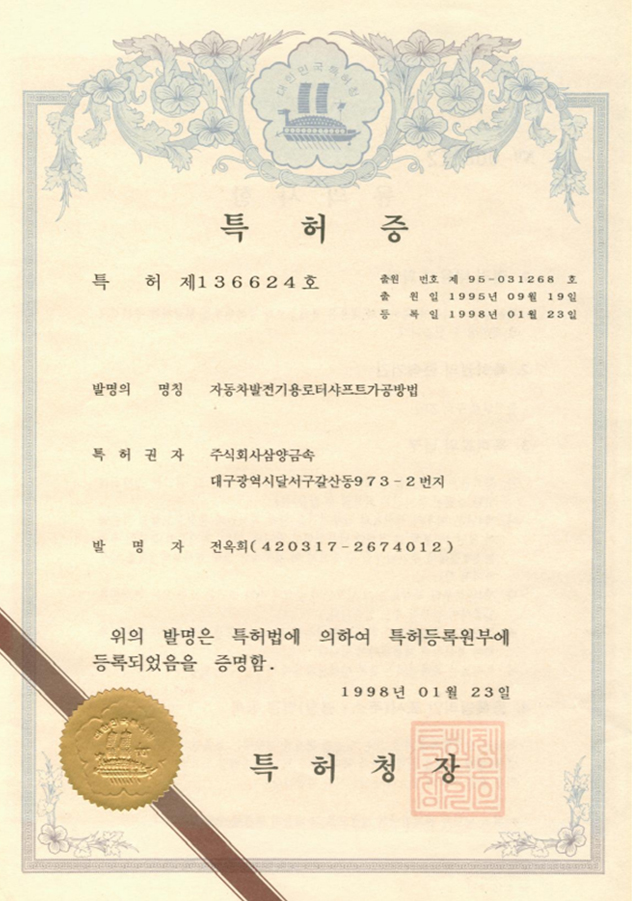

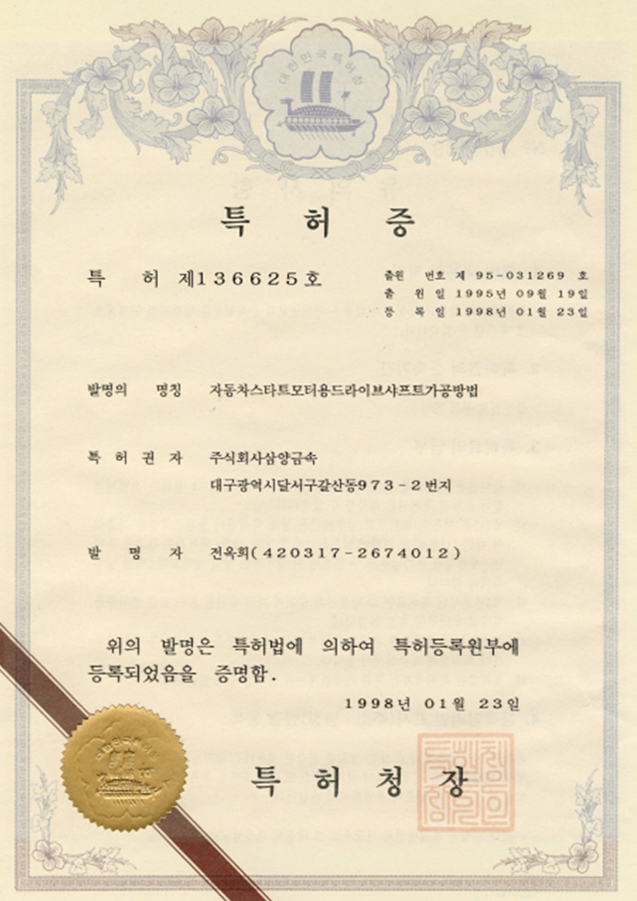

Jan. 1998 - Obtained three patents for shaft processing

methods for automobile motors.

Nov. 1998 - Received commendation from the mayor

of Daegu City for excellent small and

medium-sized businesses.

Mar. 1999 - Registered as a Venture company.

May. 2000 - Awarded Excellent small and medium

company by President.

Dec. 2000 - Acquired QS-9000 quality system

certification (Germany TUV).

Jan. 2002 - Campaign of 2002 SPS Management

Innovation.

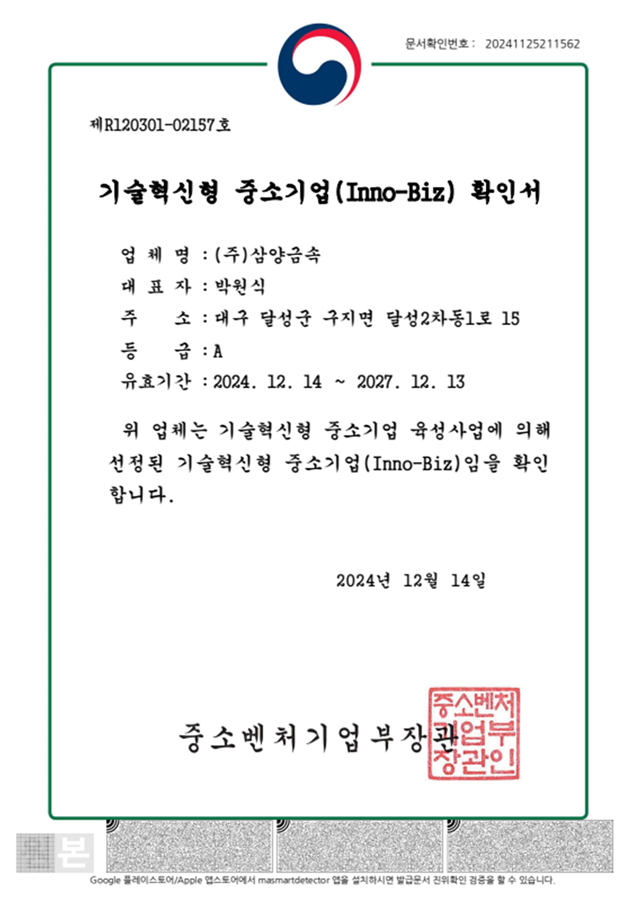

Sep. 2003 - Selected as INNO-BIZ company

(Small and Medium Business Administration).

Dec. 2003 - Awarded Best prize "Korean Production

Innovation Awards Leadership/TPS Sector”.

Nov. 2004 - Received the Labor-Management Harmony

Award (Daegu City)

Jul. 2005 - Acquired TS-16949 certification (TUV)

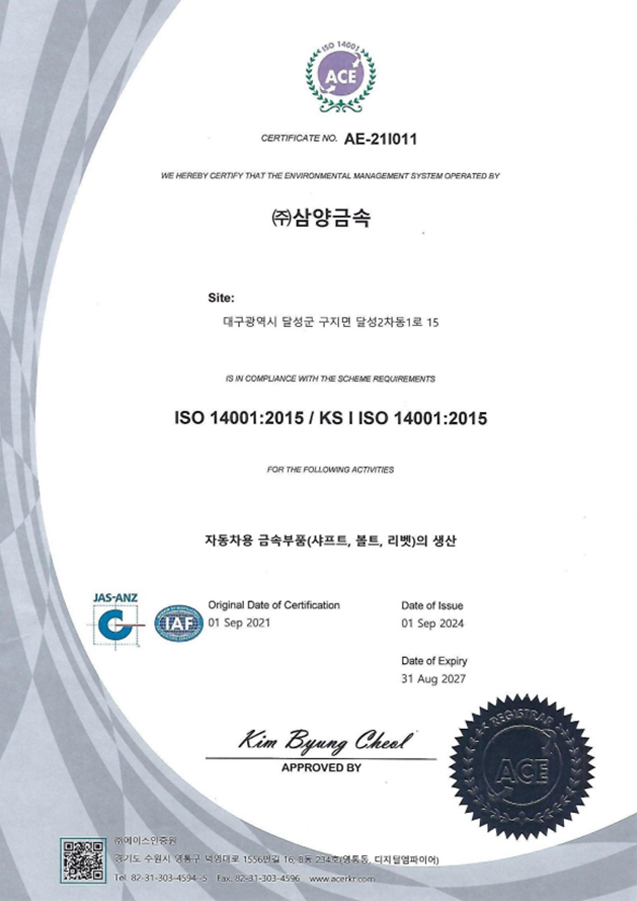

Jul. 2005 - Acquired ISO 14001:2004 certification

Jul. 2006 - Awarded “The Order of Industrial service merit”

by President.

Aug. 2007 - Move factory to “Dalseong Industrial complex”

in Daegu.

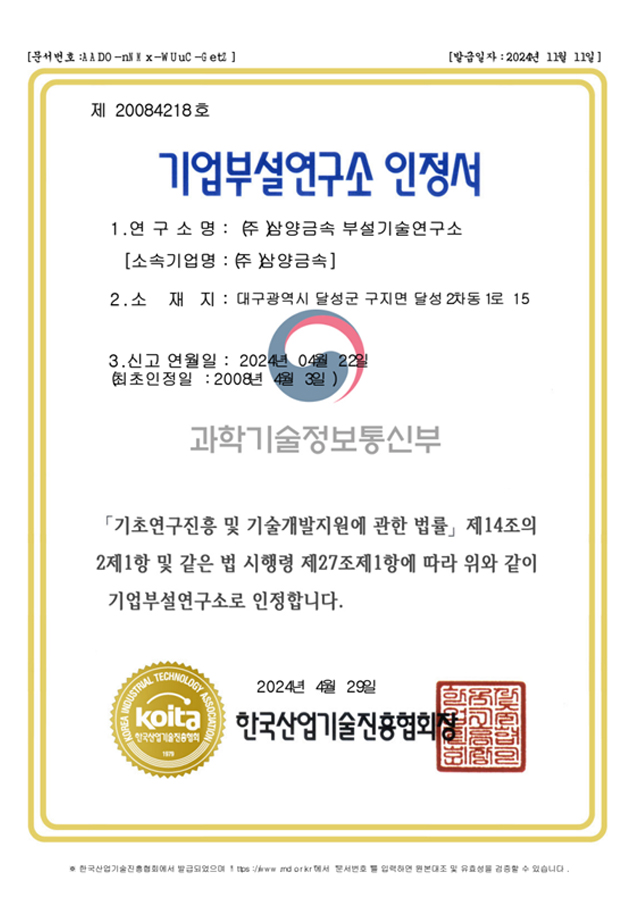

Apr. 2008 - Established the technical R&D institute in

Samyang.

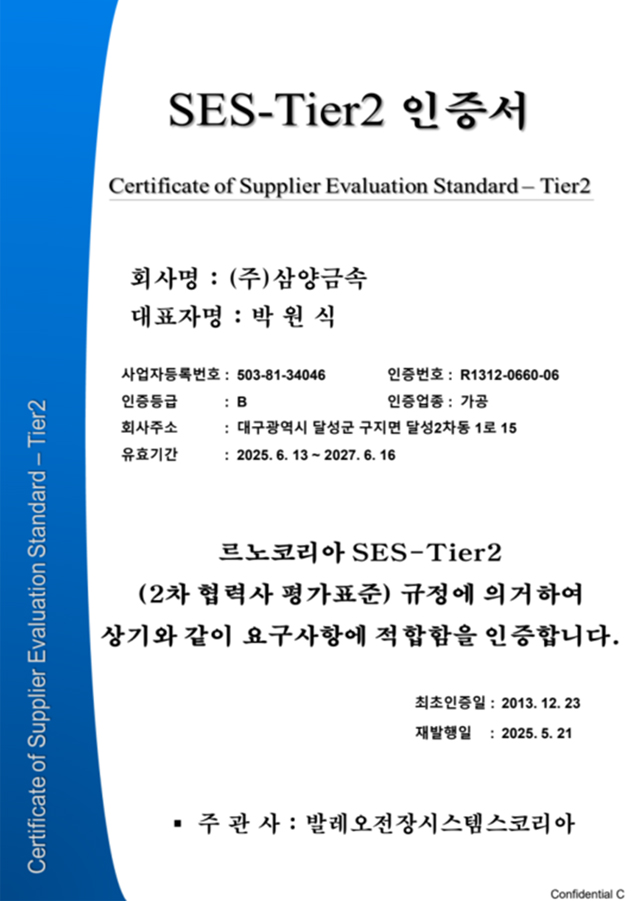

Jan. 2013 - Obtained certificate of RSM SES-Tier2.

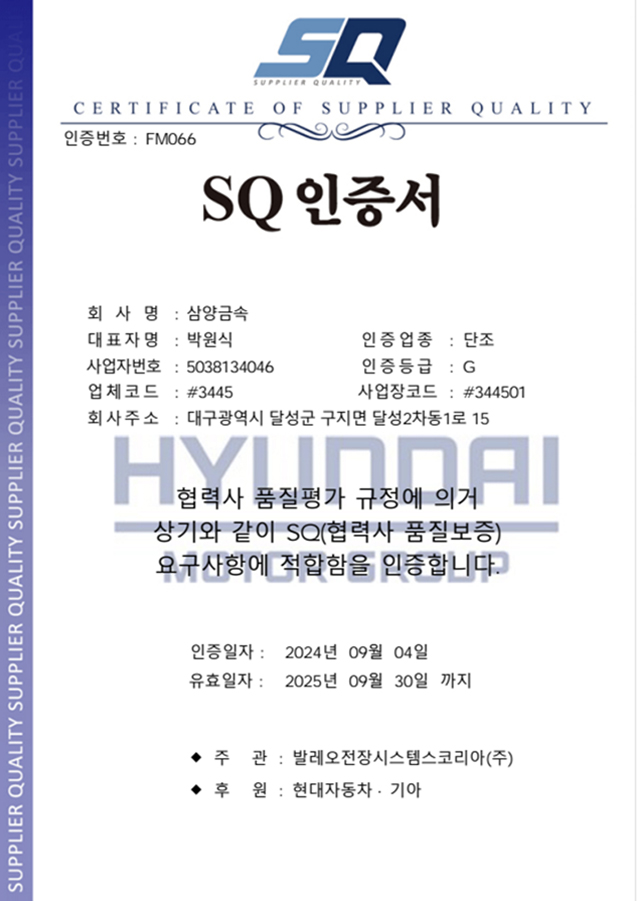

Dec. 2014 - Obtained certificate of SQ-MARK for forging

process(VEESK).

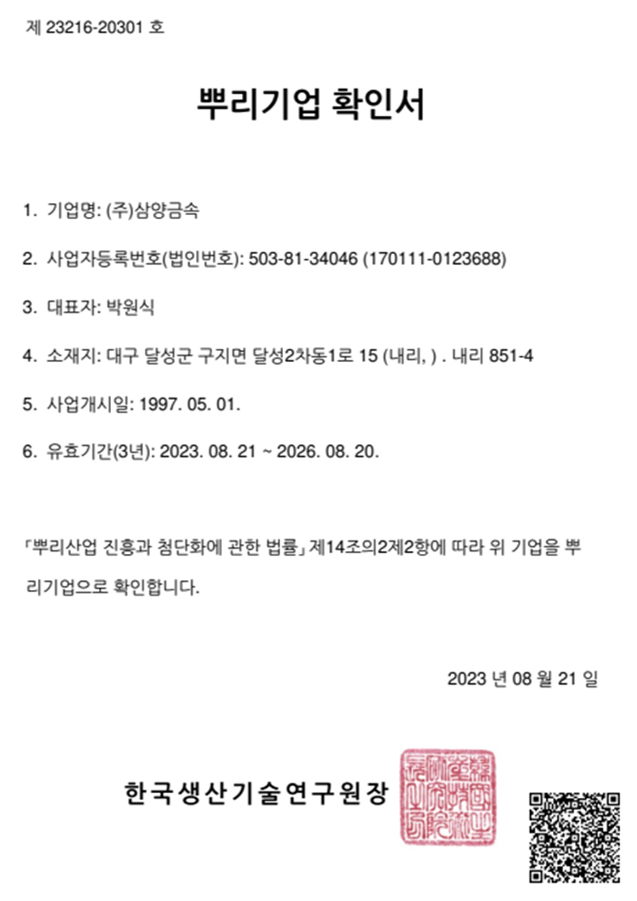

Mar. 2017 - Obtained certificate of Root-Tech Company.

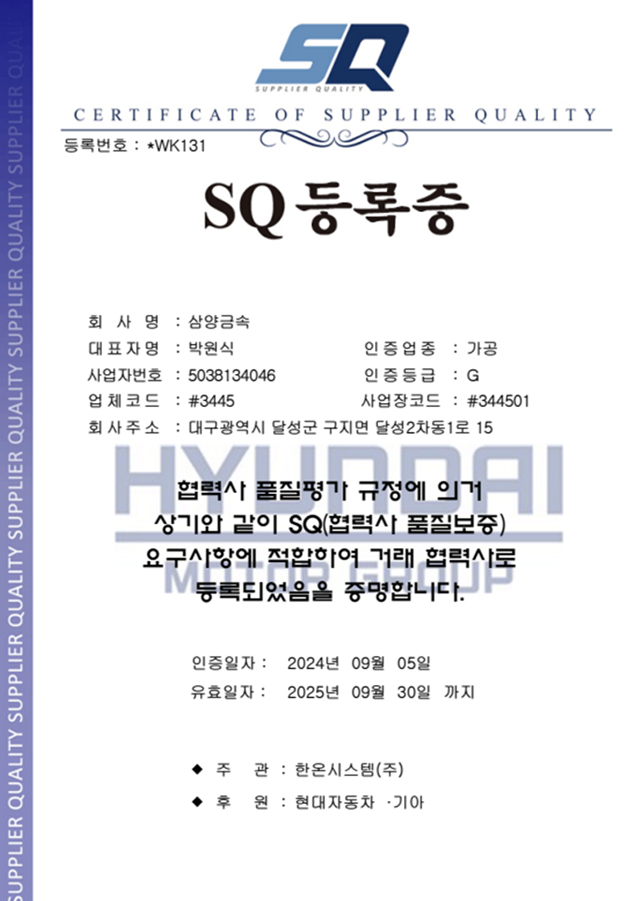

Apr. 2017 - Obtained certificate of SQ-MARK for processing

(HANON).

May. 2017 - E-building factory expansion

Dec. 2017 - Obtained certificate of SSQ-MARK (VESK).

Sep. 2018 - Obtained certificate of IATF 16949.

Dec. 2020 - Introduced smart factory system and applied

eco-friendly cold forging technology

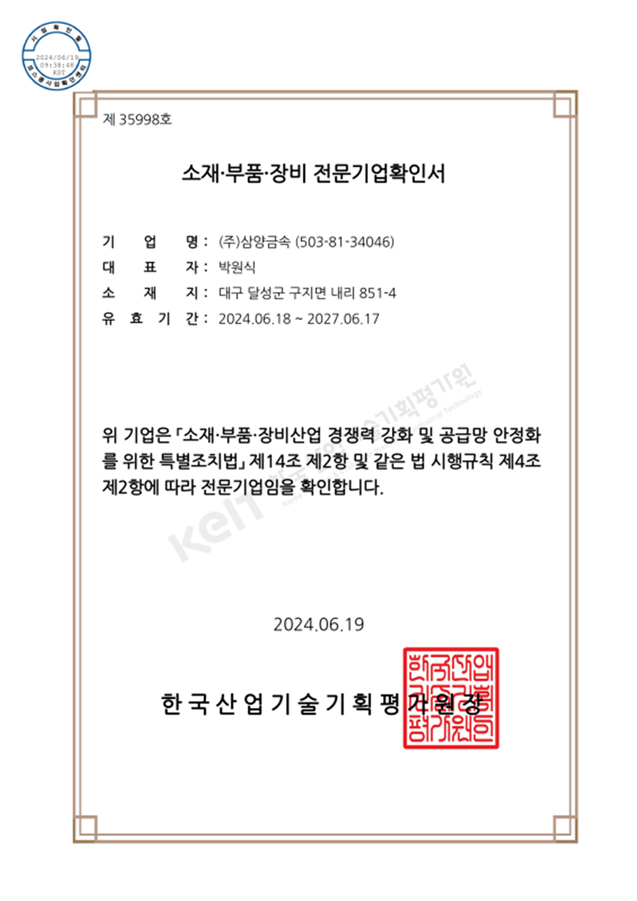

Jun. 2021 - Certified as a specialized company in materials,

parts, and equipment

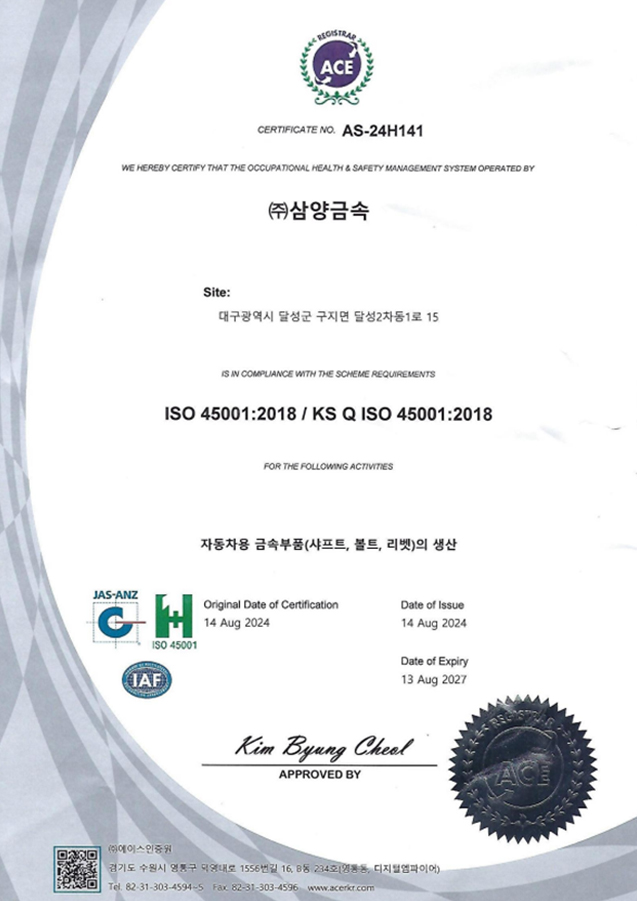

Aug. 2023 - Acquired ISO 45001 Occupational Health

and Safety Management System certification

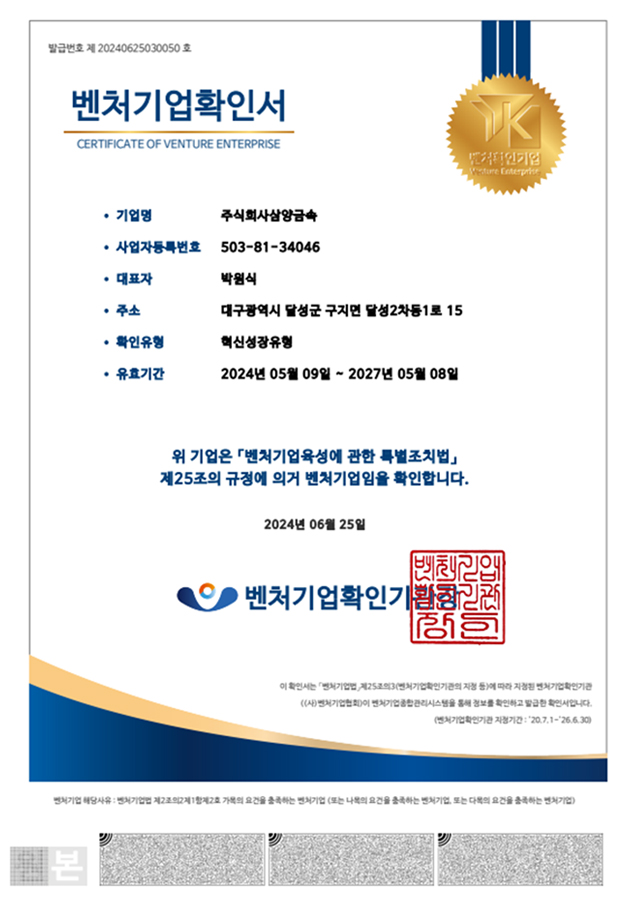

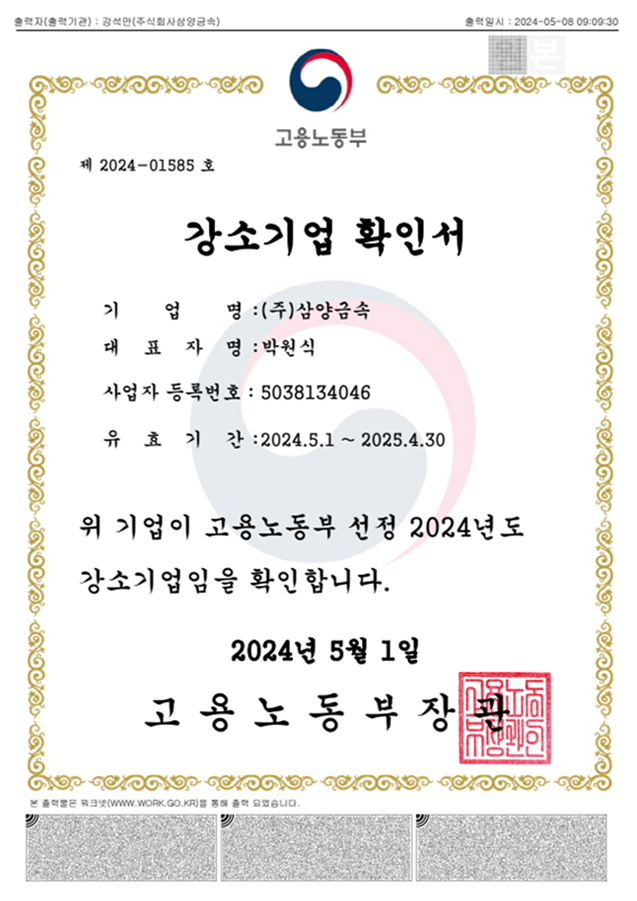

May 2024 - Certified as a "Strong Small Giant" enterprise

(Korea’s SME designation for high-potential companies)

IATF 16949:2016

ISO 14001:2015

ISO 45001 : 2018

SQ (Forging) Certificate

SQ (Machining) Certificate

SES-Tier2 Certificate

Venture companies

Innobiz

Root Enterprise

Material Parts Specialist

Small and Medium Enterprise

Corporate Research Institute

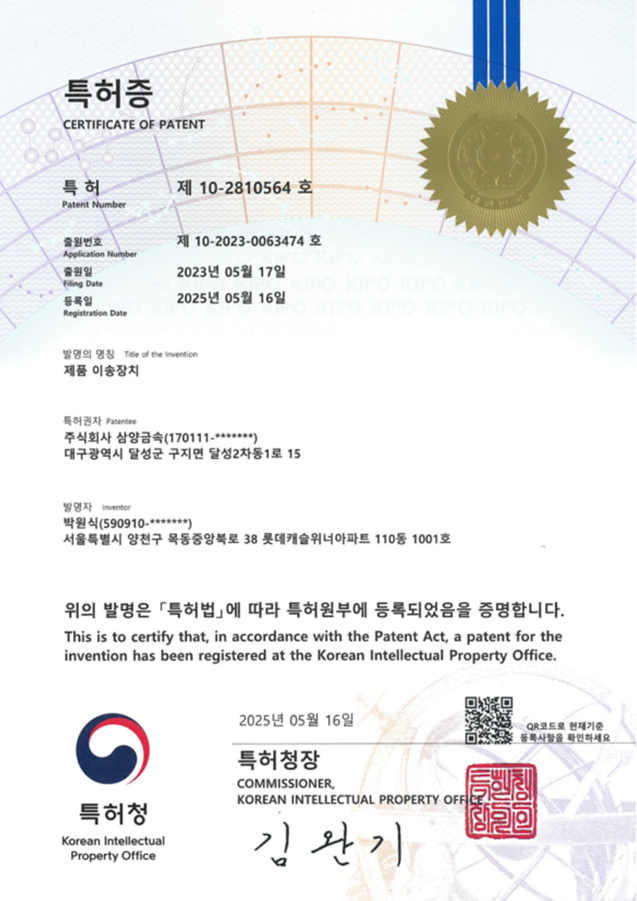

Product Conveying System

The Processing system of Rotor Shaft for Alternato

The Manufacture system of Armature Shaft for Start motor

The processing system of drive shaft for start motor

The Processing System of Armature Shaft for Start motor